RAG’s top priority is eliminating any exposure of its employees and contractors, and residents and areas affected by its operations, as well as the environment at large to risks, hazards and harm.

RAG has a proprietary health, safety and environment (HSE) management system. This establishes the framework and standards for all HSE activities, as well as mechanisms for identifying and assessing related weaknesses, the necessary corrective action, and verification of the latter.

The HSE management system establishes:

Safe installations and work processes are paramount in gas production and storage, and the development of new energy technologies. The prime objective of our HSE policies is eliminating any exposure of the Group’s employees and contractors, and residents and areas affected by its operations, as well as the environment at large to risks, hazards and harm; we aim to contribute to sustainable development.

Our approach to risk identification and appraisal is based on risk analysis. An analysis is performed annually, as part of the HSE management review, and lays the groundwork for action to manage risk. Attention is paid to identifying and assessing potential health and safety hazards at the planning stage of new projects. Projects are kept under observation throughout their life cycle, from start-up to ultimate decommissioning.

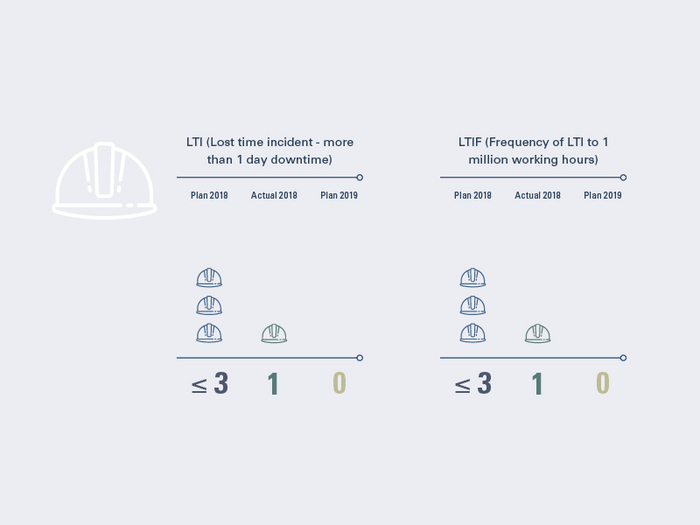

RAG’s accident prevention efforts go beyond mere compliance with statutory regulations. In all our activities we follow the zero accident goal. To achieve this, we have established a dedicated managerial unit which systematically monitors adherence to our targets on the basis of the internal HSE management system, and supports its continuous implementation and improvement.

Besides the health and safety measures designed to protect our own workforce, we also integrate contractors closely in our safety activities. Thanks to clearly defined processes, good communications, and specific guidelines and instructions, we are able to provide these workers with maximum health and safety protection. We set out to strengthen awareness of executives’, employees’ and contractors’ direct responsibility for health and safety. For example, prior to commencement of a project, we insist on all concerned performing a 5x5 matrix “last-minute risk analysis” (LMRA), so as to ensure that they are aware of the potential risks and take appropriate precautions for their own safety and that of others.

All companies working on gas production installations must submit annual reports on accidents and environmental incidents. Safety measures and training are targeted at locations we see as potentially hazardous or incident prone. The HSE management system assigns clear responsibilities, and management is fully involved in the continuous monitoring and improvement process.

In the interests of still safer operation of our plant, beyond the existing measures, in 2018 a high-level integrity manager was appointed to look after all areas of integrity management and draw up a Group report. This rates our assets in terms of their resilience in the face of disturbing influences and exceptional operating states. For example, steps can be taken to reduce the risk of an outage and to enhance system recovery capability. This particularly relates to critical infrastructure, which is assessed for its performance in black-out scenarios.

The purpose of emergency management is to get to grips quickly with events that threaten the environment, operating facilities or human health. In consultation with the responsible authorities, we have drawn up emergency plans for our main sites which include external emergency services.

If necessary, an internal crisis management team can also be put in place, to lighten the burden on the emergency management system and advise the Executive Board on strategic decisions. Regular training courses and drills, held in cooperation with the local emergency services, are used to prepare the emergency teams and crisis task force for real-life emergencies.

While digital protection is reinforced by firewalls and malware detection software, our people’s awareness of the danger of cyberattacks is raised by newsletters and training courses. Key data is also protected by encryption systems, and other technical and organisational measures.

In preparation for the applicable requirements of the NIS Directive, and in particular to safeguard our process control system, the position of a Chief Information Security Officer (CISO) has been created. This will bring an improvement in all other aspects of information security, besides IT security as such. These activities are being supported by the implementation of an information security management system.

In addition, we receive support from Austrian Energy Cert (AEC), the Computer Emergency Response Team for all members of the Austrian electricity and natural gas industry. It supports us in the detection of cyber attacks and the handling of security incidents. Within the framework of the EU NIS Directive, the AEC is the reporting office for mandatory reporting of security incidents by operators of critical infrastructure facilities.